MFMaintenance Free Roller Chain

ANSI|Single Pitch|Lube Free

“MF” type roller chains are designed to hold high quality bearing lubricant between the pin and bushing with seals. Expanded applications are now possible from low to high speeds, light to heavy loads, and where lubrication is not possible. “MF” type roller chain can drive for many hours without re-lubrication.

| SY Chain No. | Dimension - mm | Average Tensile Strength |

Average Chain Weight |

|||||||||

| Pitch | Roller | Pin | Plate | |||||||||

| Width | Dia. | Dia. | Length | Height | Thickness | |||||||

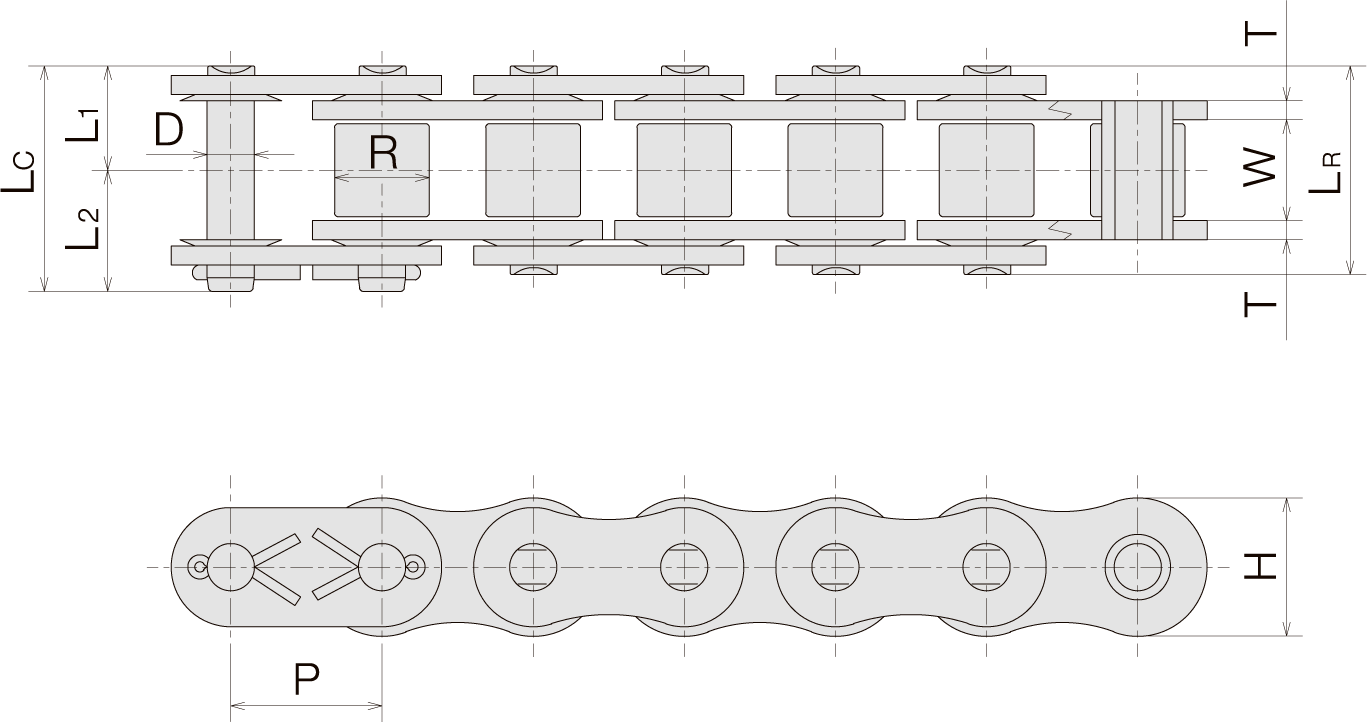

| P | W | R | D | LR | LC | L1 | L2 | H | T | KN | kg/m | |

| SY 80-1 MF | 25.40 | 15.88 | 15.88 | 7.93 | 36.4 | 38.7 | 17.8 | 20.9 | 23.4 | 3.2 | 73.00 | 2.6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SY 100-1 MF | 31.75 | 19.05 | 19.05 | 9.53 | 42.4 | 45.8 | 21.2 | 24.6 | 29.3 | 4.0 | 116.00 | 3.9 |

| SY 120-1 MF | 38.10 | 25.40 | 22.23 | 11.10 | 52.2 | 56.4 | 26.1 | 30.3 | 35.1 | 4.8 | 164.00 | 5.8 |

| SY 140-1 MF | 44.45 | 25.40 | 25.40 | 12.70 | 56.7 | 61.3 | 28.4 | 32.9 | 40.9 | 5.6 | 216.00 | 7.5 |

| SY 160-1 MF | 50.80 | 31.75 | 28.58 | 14.28 | 67.0 | 72.2 | 33.5 | 38.7 | 46.7 | 6.4 | 275.00 | 9.8 |

| SY 200-1 MF | 63.50 | 38.10 | 39.67 | 19.83 | 80.7 | 89.7 | 40.4 | 49.3 | 59.8 | 8.0 | 451.00 | 16.9 |

| SY 240-1 MF | 76.20 | 47.63 | 47.63 | 23.78 | 98.6 | 107.2 | 49.3 | 57.9 | 70.3 | 9.5 | 677.00 | 23.6 |

MF type chains are designed to be used with standard sprockets. MF type roller chains have a longer pin than the SBR type roller chain. Make sure there will be no interference with equipment. Connecting links for MF type are "semi press-fit" style. Check that each pin and bushing is well lubricated and has a seal in each joint before connecting link is assembled with the chain itself. Service life decreases dramatically if the lubricant between the pin and bushing is depleted. It is not recommended for applications which are exposed to chemicals or water, or associated with a shock load. Due to friction between the plate and the seal, the stiff joint is tighter than the standard roller chain. Offset links are not available. MF type chains are only available with a riveted type design.