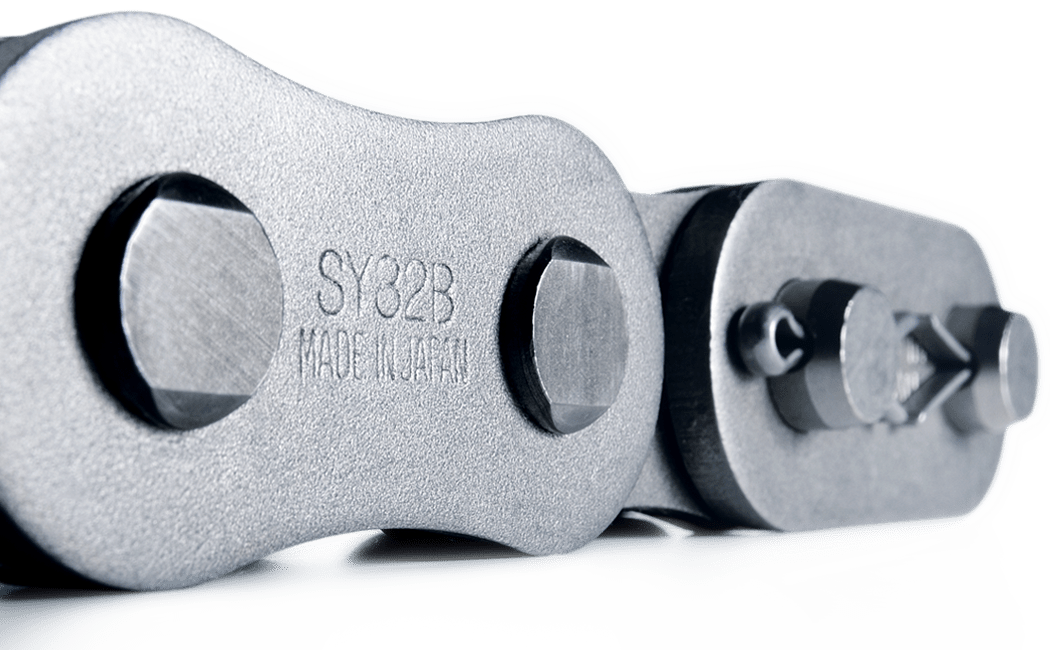

Solid Bushings & RollersPremium SBR®

Chain components require a precision of 1/100mm. To make their molds, a micron-level accuracy which is one scale further down is needed. At our early stage, we worked on in-house production of precision molds and developed our own unique method of producing.

Our roller chain has built a reputation as a first-tier product in the world to date. Our outstanding technologies as a leading manufacturer enable to develop products that lead one step ahead of competitors.

SBR (Solid Bushings and Rollers) chain was created through product development that brought all of our best technologies together.

01Significantly longer wear life

Conventional split bushings deform into a barrel shape when side plates are pressed on, leaving only two-point contact area. SBR (Solid Bushings & Rollers) chain has extremely cylindrical inside bushing and roller walls resulting in full contact to disperse bearing pressure. Less pressure ensures excellent wear resistance.

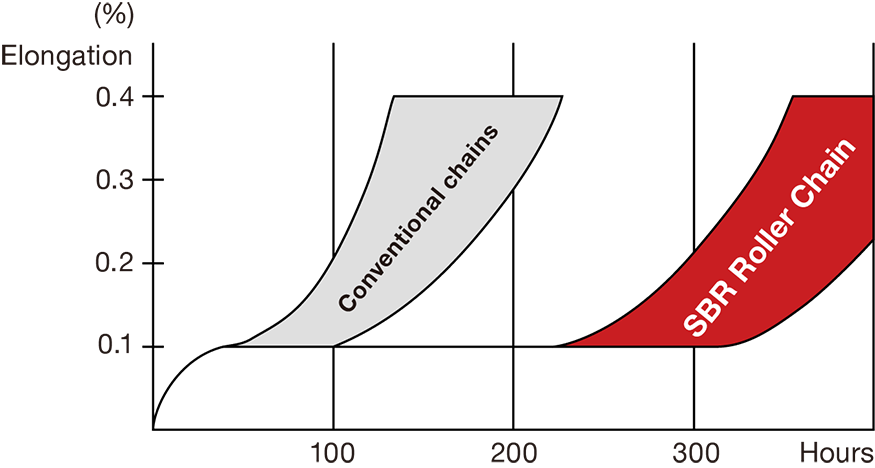

〈Wear resistance test〉

02Up to 2-3 times longer wear life over curled bushings chain.

The curled, split bushings have a seam where tiny space allows lubricant leakage resulting in shorter wear life. SBR has no seam resulting in lower bearing pressure allowing the bushings to retain lubrication resulting in much longer wear life.

03Reliable Performance

SBR is cold-forged from steel rod. Cold-forming process also works with the molecular structure (grain) of the steel running lengthwise in the bushings thereby increasing fatigue strength and preventing bushings from breakage. Premium SBR chains improve performance of transmission with lesser elongation for long period of time.

Higher Maximum Allowable Load

Specially treated pin contributes to increase fatigue strength.

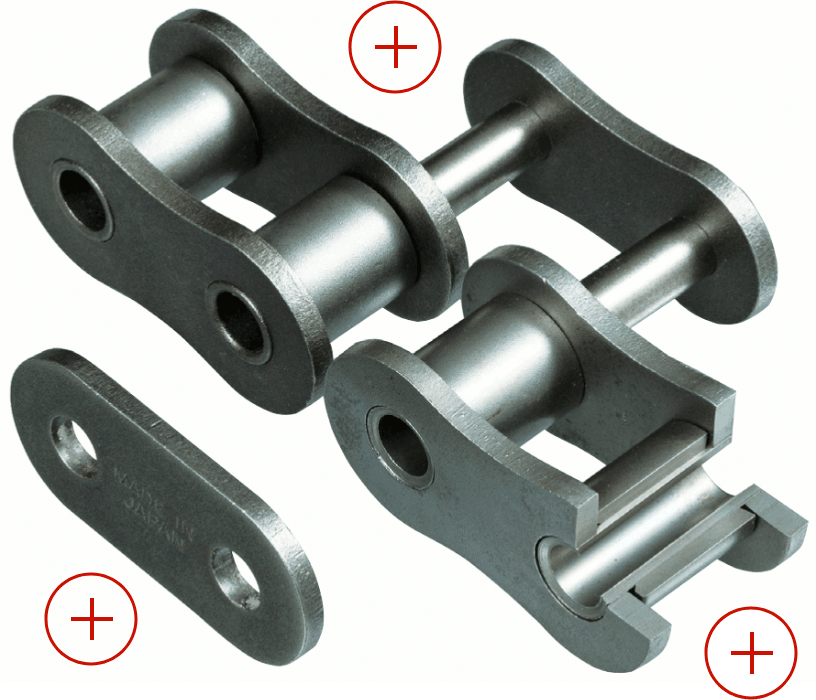

Solid Bushings & Solid Rollers (SBR)

Longer service life is achieved due to seamless solid bushing and solid roller. Cold-forging process help maintain a totally cylindrical inside diameter even after assembly.

Connecting Link

The connecting link has the same strength as chain itself.

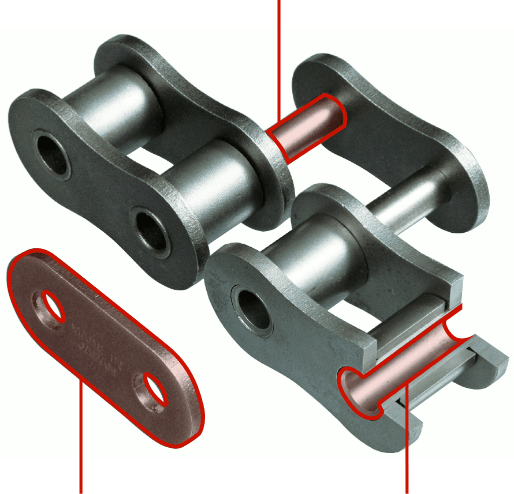

The difference between “Conventional Chain” and “SBR Chain”

Conventional Chain

SBR Chain

Conventional Chain

In assembling a split curled bushing with the roller link side plates, the bushing become “barrel-shaped”.

SBR Chain

Our solid bushings and rollers are cold forged from solid bar stock. The solid bushing does not deform when it is assembled with the roller link side plates.

Conventional Chain

Uneven contact between pin and bushing create excess heat and wear very quickly causing chain stretch.

SBR Chain

Full pin-bushing contact retains Inbrication longer, reduces heat and wear, and greatly reduces elongation.